AI-based Process Analytics and Control on the Shop Floor (AIPACS)

The progressive adoption of IT systems and machine digitization lead to the creation of ever greater quantities of data in the manufacturing domain. Simultaneously, the complexity of shop-floor operation and control is increasing while product life cycles shorten, and customer expectations rise. Data-driven methods promise to mitigate the increased complexity while realizing potentials for service improvement, cost reduction and energy savings. The sophisticated application of such methods is becoming a decisive factor for the competitiveness of manufacturing firms.

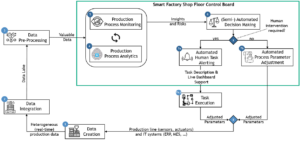

The AI-based Process Analytics and Control on the Shop Floor (AIPACS) project aims to increase shop floor control by applying AI-based methods to make use of the heterogenous data sources of the shopfloor (i.e., production line sensors and IT-Systems). The concept of the research project is shown on the right. By integrating the necessary data into a data-lake the processability of the differing data sources is ensured. After a pre-processing step, AI- and other data-driven methods are applied in the production process analytics step. The resulting models and algorithms are then used in the monitoring step. If a process relevant deviation is predicted or detected, the deviation is either corrected by the system itself or an employee gets notified with a correction task. In both cases the correction measure will lead to adjusted parameters which are observable in the data sources. The observed adjustments can then be used as a feedback loop to enhance the continuous cycle of analysis and monitoring.

Researcher

Partner

REHAU Industries SE & Co. KG